Edit Content

Get in touch

Lorem ipsum dolor sit amet constute emire. Email us: [email protected]

Talk to us

Office

Paradise Road 70, Office 99, Pacific Bay, New York City 10010

Help

Visit Help Center

Lorem ipsum dolor sit amet constute emire. Email us: [email protected]

Paradise Road 70, Office 99, Pacific Bay, New York City 10010

Visit Help Center

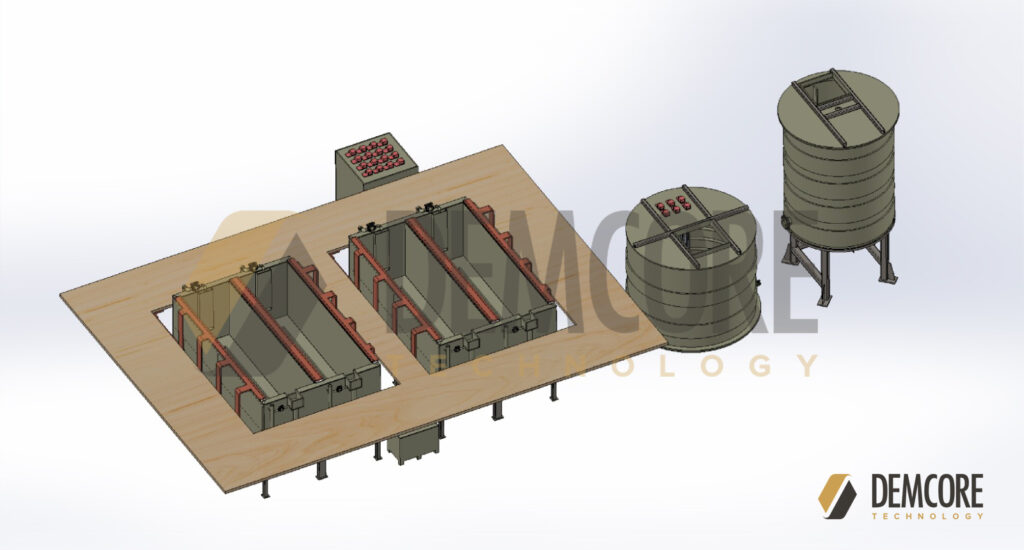

The electrolysis plant is the last step necessary for the production of cathode copper from the anodes obtained. There are four electrolysis plants in our country and two of them were built by us.

While the sulfuric acid and copper sulfate-based electrolyte circulation is carried out in specially designed PP-H pools, the copper ions in the anode pass to the cathode. This process is called electrolysis.

TECHNICAL SPESIFICATION | |

Number of Cell | Up to Design |

Cell Material | PP-H |

Circulation Pump | Included |

Anode Capacity | 6 Anode ( Up to Design) |

Cathode Capacity | 7 Cathode ( Up to Design) |

Cathode Dimensions | Up to Design |

Cathode Bus Bar | Included |

Cathode Sheet | 316 SS |

Cathode Side Edge | Included ( PP-H) |

Cell Bus-Bar | Included |

Bus-Bur Isolation | PVC-U |

Circulation Tank | Included |

Heating Tank | Included |

Heating System | Included |

Mud Tank | Included |

Gelatine Dosing system | Included |

Thio-urea dosing system | Included |

NaCl Dosing system | Included |

Sludge filtration system | Included |

Decantation tank | Included |

Rectifier | Included |

Rectifier Type | Switch Mode |

Cell Voltage | 0.35 V ± 0.05 V |

Cathode Current Density | 240-300 A/m2 |

Ripple Value | < 10 % |

Rectifier Bus Bar | Included |

Pb-Sb Anode | Included |

Vadi Istanbul Bilisim Vadisi Teknopark Blok Kat :2 – Sarıyer / ISTANBUL

Koseler Mahallesi 3. Cadde No:39 Dilovasi / KOCAELI

Copyright © 2024 Demcore Technology. All rights reserved.