Edit Content

Get in touch

Lorem ipsum dolor sit amet constute emire. Email us: [email protected]

Talk to us

Office

Paradise Road 70, Office 99, Pacific Bay, New York City 10010

Help

Visit Help Center

Lorem ipsum dolor sit amet constute emire. Email us: [email protected]

Paradise Road 70, Office 99, Pacific Bay, New York City 10010

Visit Help Center

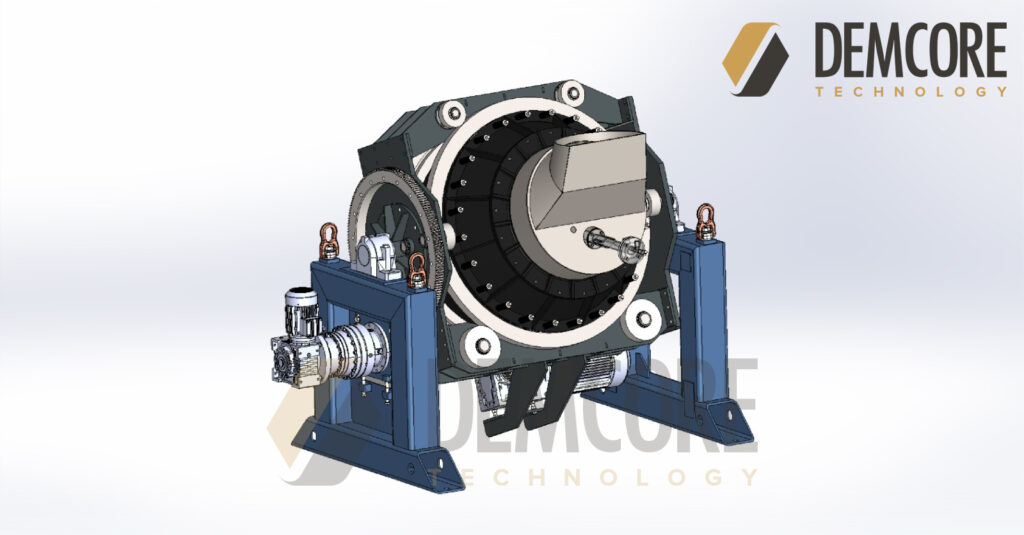

TBRC melting systems are the most effective furnace type used in melting electronic waste, catalytic converters, copper-based waste and blister copper.

Charging and melting time depends on the type, quality and consistency of the scrap input.

A melting cycle includes the following processes:

| Technical Details | |

| Melting Capacity | 25-100 kg PCB / Batch |

| Melting Temperature | Max 1300 oC |

| Total Volume | 120 Liter |

| Effective Volume | 55 Liter |

| Slag Area | 55 Liter |

| Bath Depth | 650 mm |

| Working Hours | 24 hours / day |

| Rotation Speed | 0-10 rpm |

| Tilting Angle | -35o (Melting ) |

| +10o ( Casting) | |

| Tilting Speed | 40 sec |

| Operation Unit | Tilting: Gearbox + Gear |

| Rotation: Gearbox + Gear | |

| Door : Manuel | |

| Oxidation Lance | Included |

| Burner System | |

| Number of Burner | 1 |

| Burner Type | Oxy-Fuel Burner |

| Burner Capacity | 300 kw / h |

| Gas Regulation | Valve Train |

| Fuel | |

| Natural Gas | 300 bar |

| Oxygen | 1-2 Bar |

| Max. Natural Gas Consumption | 300 m3 / h |

| Nominal Natural Gas Consumption | 200 m3 / h |

| Max. Oxygen Consumption | 650 m3 / h |

| Nominal Oxygen Consumption | 420 m3 / h |

| Refratory | |

| Working Refractory Chromium Magnesite | |

| Safety/Isolation Refratory | Alumina |

| Isoloation | Ceramic Fiber |

Vadi Istanbul Bilisim Vadisi Teknopark Blok Kat :2 – Sarıyer / ISTANBUL

Koseler Mahallesi 3. Cadde No:39 Dilovasi / KOCAELI

Copyright © 2024 Demcore Technology. All rights reserved.